Shiang-Jiun

ABOUT US

Shiang-Jiun Industrial Co., Ltd was founded in 1989 and specialized in sheet metal manufacturer. We optimize supply chain comprehensive one-stop solution from concept to product.

As Shiang-Jiun Industrial’s business philosophy " Exceed Customer Expectations ". We have been developing OEM/ODM products for more than 30 years with the trend of the times and develop the comparative advantages with precision equipment. Various customized products are provided based on the needs of customers, including computer related products, components, furniture, fundamental facilities and medical device, etc. To achieve the goal of sustainable business operation. We always “Think Globally, Act Locally!”

As Shiang-Jiun Industrial’s business philosophy " Exceed Customer Expectations ". We have been developing OEM/ODM products for more than 30 years with the trend of the times and develop the comparative advantages with precision equipment. Various customized products are provided based on the needs of customers, including computer related products, components, furniture, fundamental facilities and medical device, etc. To achieve the goal of sustainable business operation. We always “Think Globally, Act Locally!”

service

-

2D&3D DrawingWe have an experience 2D&3D drawing team, they can quickly provide a professional suggestion.

-

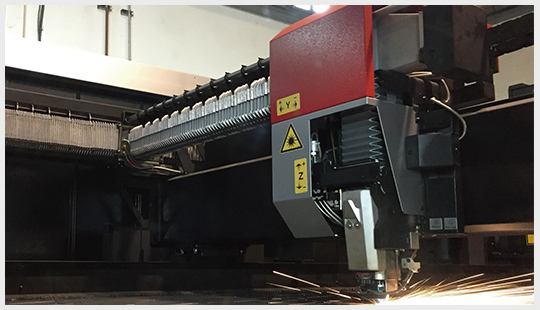

Laser CuttingOur factory has upgraded to precision equipment and introduced Japan Amada Laser Cutting Machine to increase diverse manufacturing lineSPHC (working thickness)0.6mm-19mm

Laser CuttingOur factory has upgraded to precision equipment and introduced Japan Amada Laser Cutting Machine to increase diverse manufacturing lineSPHC (working thickness)0.6mm-19mm

Aluminum (working thickness)0.6mm-5.0mm

SUS304 (working thickness)0.6mm-15mm -

Mold Development & ManufacturingWe have more than 30 years mold development team to provide molds in the shortest time. With high efficiency and reducing the cost.

-

Sheet Metal StampingWe have over 30 years of professional skills and experience in stamping equipment, and there are 27 units differences types of stamping machines for various stamping needs.

Sheet Metal StampingWe have over 30 years of professional skills and experience in stamping equipment, and there are 27 units differences types of stamping machines for various stamping needs.

(8 tons to 350 tons) -

Sheet Metal BendingWe introduced AMADA precision computer bending lath models to improve the product quality and meet the international standard.(Maximum processing length 3 meters)

-

WeldingIn our factory, there are multiple units of “Robotic laser welding”,” Robotic CO2 welding machine”, “Spot welding machine” and “Argon welding machine” to achieve high quality and high efficiency welding standards.

WeldingIn our factory, there are multiple units of “Robotic laser welding”,” Robotic CO2 welding machine”, “Spot welding machine” and “Argon welding machine” to achieve high quality and high efficiency welding standards. -

TappingThere are various models of tapping machines to satisfy all kinds of tapping requirements.

-

Quality ControlBased on the ISO-90001 international standard,

Quality ControlBased on the ISO-90001 international standard,

we measure the product on the process and before shipping. -

Powder CoatingWith GEMA (Switzerland GmbH’s) auto-electrostatic devices coat spray booth. The powder uniformed coated on every surface of workpieces. Environmentally friendly, energy-saving, waste deduction and better productivity.

-

PackingIntroduce linear packaging production line in 2022

PackingIntroduce linear packaging production line in 2022